Volvo Group UK Limited was fined £13,333 after an employee at the Cardonald Depot was crushed by a truck, leading to serious injury.

The circumstances were:

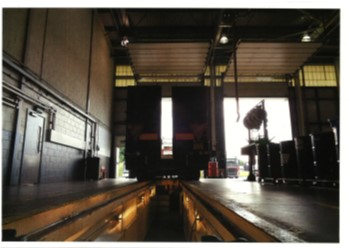

- On 7 June 2016 an employee of Volvo Group UK Limited was testing the brakes of a low-loader truck unit and trailer at the Cardonald depot.

- Volvo Group UK Limited failed to provide a sufficient number of wheel chocks for use by its employees.

- They also failed to provide information, instruction, supervision and training of its employees in their use.

- They also failed to provide a suitable induction of the employee in safe working practices.

- The employee raised the trailer off the ground using a pit jack.

- He did not apply the truck handbrake or use any wheel chocks to prevent the vehicle rolling.

- Whilst adjusting the brakes at the first axle, the truck unit rolled forward causing the jack to slip off the axle of the trailer, roll towards him and strike him on the body, crushing him against a set of steps in the pit and fracturing his spine.

The HSE Inspector said:

“Those in control of work have a responsibility to devise safe methods of working and to provide the necessary information, instruction and training to their workers in the safe system of working. If a suitable safe system of work had been in place prior to the incident, the life changing injuries sustained by the employee could have been prevented.”

“Those in control of work have a responsibility to devise safe methods of working and to provide the necessary information, instruction and training to their workers in the safe system of working. If a suitable safe system of work had been in place prior to the incident, the life changing injuries sustained by the employee could have been prevented.”