Furniture manufacturer, A and L Furnishings Ltd, was fined £19,500 (inc.costs) after an employee was injured whilst operating unguarded machinery.

The circumstances were:

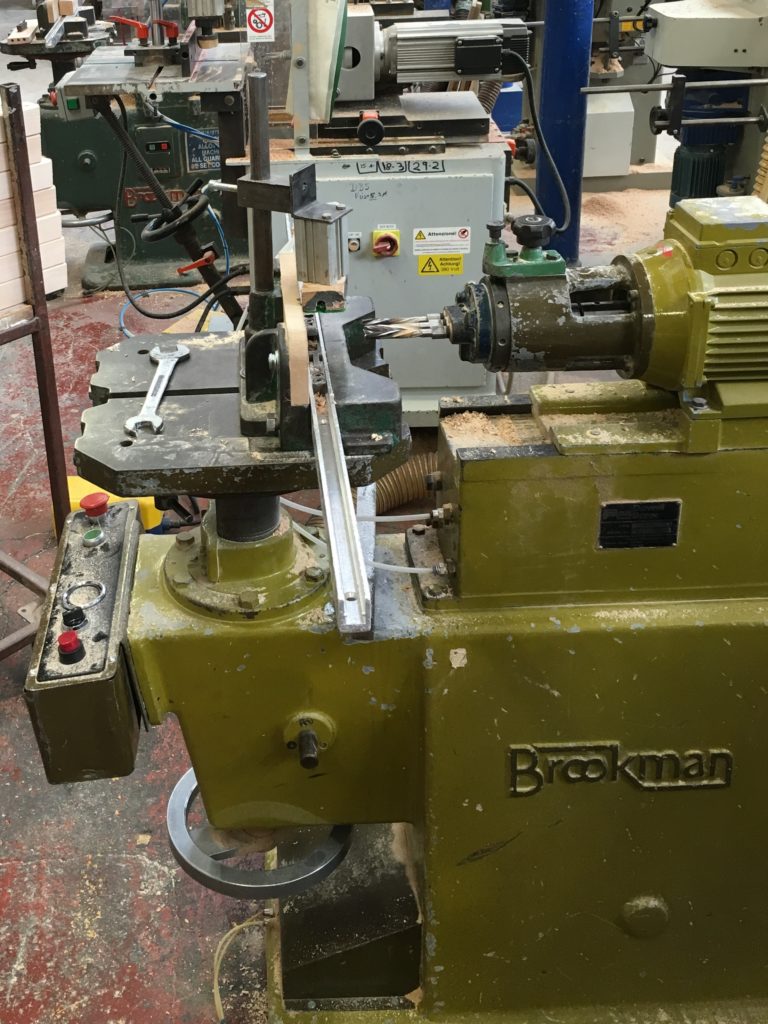

- The accident occurred on a horizontal drilling machine.

- There was no guard preventing access to rotating drill bits.

- On 19 March 2018, an employee was using a horizontal drilling machine to make parts for a chair.

- The fingers of his left hand came into contact with unguarded counter-rotating drill bits and became entangled.

- The incident caused extensive damage to his left hand, resulting in the amputation of two fingers.

The HSE inspector said:

“The dangers of unguarded machinery are well-known. If A and L Furnishings Ltd had ensured that suitable guarding was in place, then this incident would have been avoided. Companies should be aware that HSE will not hesitate to take enforcement action when the required standards are not met.”

“The dangers of unguarded machinery are well-known. If A and L Furnishings Ltd had ensured that suitable guarding was in place, then this incident would have been avoided. Companies should be aware that HSE will not hesitate to take enforcement action when the required standards are not met.”