Waste recycling firm Stonegrave Aggregates Ltd., was fined £248,952 (inc costs) and its director and site manager sentenced after an employee died and a second employee was seriously injured when they became trapped inside machinery.

The circumstances were:

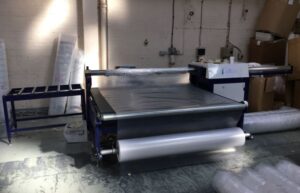

- The accident occurred on a waste processing line.

- This included a trommel, incorporating a large perforated revolving drum, which acts to agitate, rotate and sieve the waste materials.

- The line was not adequately guarded to prevent access to dangerous parts of machinery.

- Control systems, including emergency stop controls, were not compliant with relevant standards.

- Management did not adequately monitor or enforce machinery isolation procedures.

- What guarding was provided to the trommel was being regularly bypassed by staff.

- This included the site manager David Basham.

- On 12 December 2015 the line became blocked at various points including the trommel.

- Two employees, Simon Hogg and Raymond Garret, stopped the trommel and entered the drum to clear the blockage.

- There was no isolation and lock-out procedure in place.

- Two other employees, who were unaware that they were inside the machinery, restarted the production line.

- Mr Hogg and Mr Garrett remained inside the revolving trommel drum for approximately four minutes before the line was stopped and the two men were found inside.

- Simon Hogg died at the scene after sustaining multiple injuries to his head and torso.

- Raymond Garrett sustained multiple serious injuries to his legs, arms and torso requiring extensive hospital treatment.

Director of Stonegrave Aggregates Limited Bruce Whitley was given a 12-month community order.

Site manager at Stonegrave Aggregates Limited Aycliffe Quarry site David Basham was given a six-month prison sentence suspended for 12 months.

The HSE inspector said:

“These tragic consequences could have been avoided. This case highlights the importance of implementing effective power isolation procedures when interacting with machinery and the need to monitor compliance to make sure these procedures are followed. HSE will not hesitate to prosecute companies or individuals who fail to implement and monitor safe systems of work.”